Global vehicle sales projections – going from the most pessimistic to most optimistic estimates – indicate between 50 to 150 million EVs will be sold by 2030. Within next 10 years, EVs expected to outsell gasoline vehicles in most markets. Even in India, EV sales for 2 and 4 wheelers grew by 20 per cent in 2019-20. McKinsey, however, has put India under 1 out of 5 score on its Global Electric Vehicle Index’s both dimensions – Market adoption and Industry leadership. Out its 15 countries indexing, India ranks lowest on market adoption score, and 7 th in EV Industry leadership. For being the 4 th largest automotive market globally, it is important for Indian automakers to gear up for indigenous EV development and upskill its legacy teams.

Engineering a system as complex as an EV to meet the requirements of emerging market like India, which is hyper-sensitive in terms of price as well as performance, can be quite a challenge. Other complexities it poses is its very unique traffic conditions and driving styles. India has witnessed many global bestsellers failing in its market due to lack of a consumer-centric approach towards its buyers.

As consumers in developing economy no longer look for confirmation from developed countries for their needs, a bottom-up approach of engineering starting with understanding the customer usage typical to the region of sales is fast becoming a success formula. The vital component of this approach is the virtual model-based development, which can simulate any customer behavior in any region and provide vital inputs to forming vehicle technical specifications. These can further be cascaded to sub-system specifications and component design targets. Virtual model-based development also helps apply the customer usage effects as load cases in design activities, which helps optimize the design for a cost-effective and robust product which everyone likes to use.

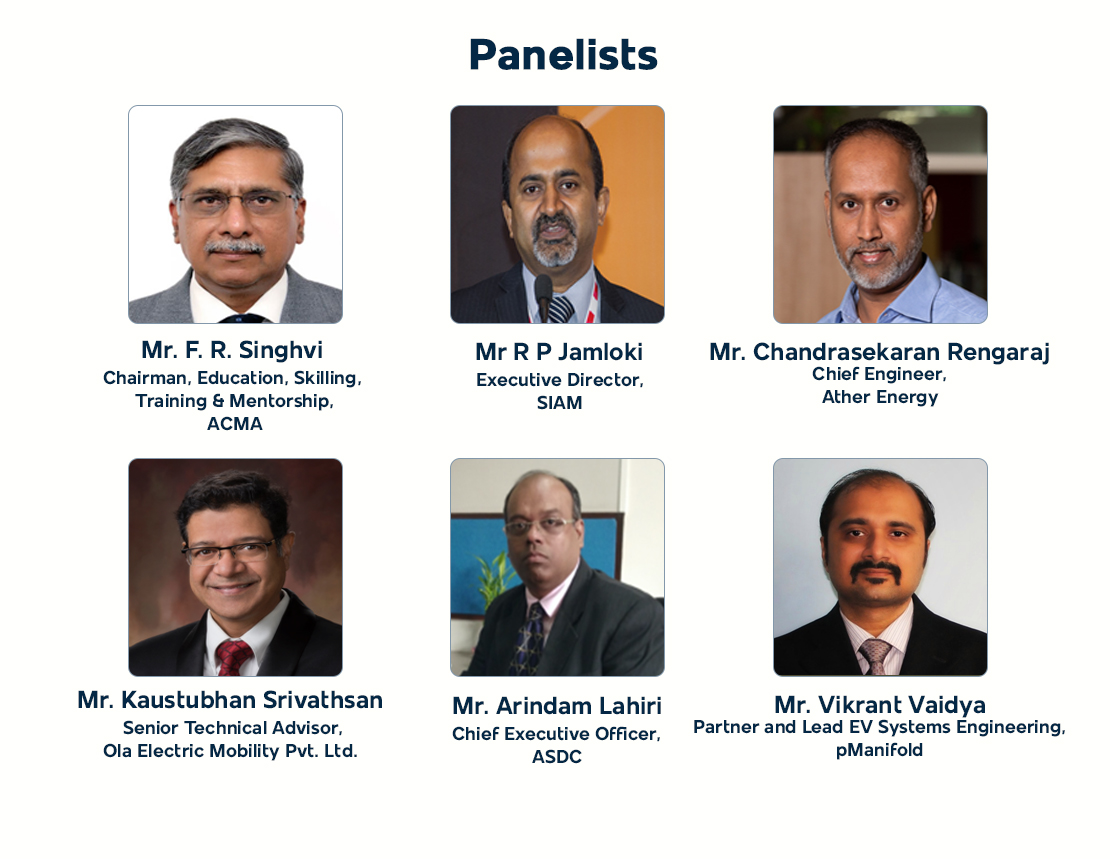

This Webinar will bring experts from multiple domains – Pure EV OEM, Mix ICE and EV OEM, Automobile/ EV Industry Association to discuss following questions:

- What typical product development cycle followed by automobile manufacturer, and role and impact of modeling and simulations?

- What going forward trends in digitalization of product design and development, including testing and calibration by the OEMs?

- What skill requirements in product design, prototyping, development, testing, calibration teams to speed up and improve overall reliability and performance of EVs?

- Any particular skill gaps in EV teams when compared to mature ICE industry? What trainings would be beneficial?

- How to develop right teaching and learning ecosystem on-site at OEMs, and also Engineering education system to advance EV knowledge and hands-on skills?