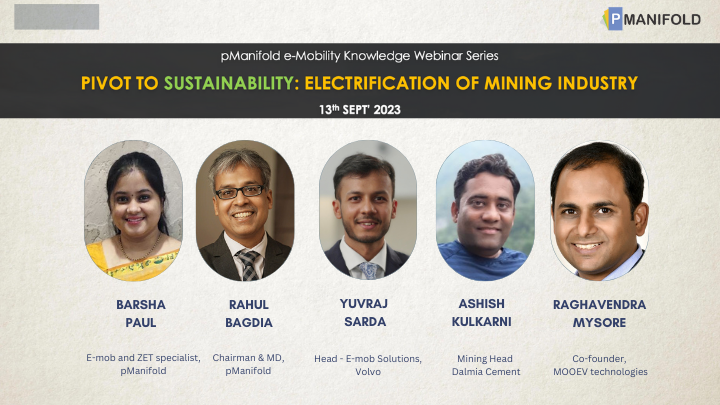

Our Experts:

Rahul Bagdia – Chairman and MD, pManifold

Barsha Paul – e-mobility and ZET Expert, pManifold

Yuvraj Sarda – Head, e-Mobility solutions, Volvo Group

Ashish Kulkarni – Mining Head, Dalmia Cements Limited

Raghavendra Mysore – Co-founder, MOOEV technologies

Challenges in the mining-

Availability of the mineral (Minerals present at greater depths)

Operational costs

Fuel prices rising up

Operational challenges

Underground emissions affecting health’s of the works and productivity

- The electrification of the off-highway sector in India is still in its early stages. Over the past few years, the focus has primarily been on electric two-wheelers, three-wheelers, some electric commercial vehicles, and a handful of electric cars. With the introduction of the Pradhan Mantri e-bus seva, our attention has now shifted significantly toward electric buses. However, when it comes to off-highway machinery, trucks, and construction equipment, the inherent challenges have led to them being less considered candidates for electrification in the Indian context.

- As we delve into the realm of solutions and assess their economic viability, we are beginning to recognize certain gaps.

- Hydrogen as a fuel has higher energy density and can power bigger class machinery but has quite high volume, and has challenges in terms of storage and transportation. The solution can revolve around using hybrids (smaller battery + Fuel Cells/ biodiesel).

- The economies of scale is very important in this context, considering the uniqueness of each mining site, equipment, and the technology tailored to specific companies.With the diverse and site-specific nature of mining operations, a customized approach to equipment and technology becomes crucial.

- Within the same industry and even across various types of mines, each operation presents unique challenges and requirements. The demands of a coal mine, for instance, can vary significantly from those of a cement mine, with distinctions arising from factors such as depth, gradients, and geological conditions. It’s important to recognize that the mining environment, with its diverse landscapes and conditions, ranks among the most challenging in terms of vehicle technology and capabilities.

- Mining electrification is a great segment to look at purely from the both from the first resistance and looking at the system as a whole.

- Currently, for cost effective solutions companies prefer using biodiesels as well as heat XL diesel where the cost of diesel is near about 10-15 rupees, instead of electrification. But this practice is not sustainable in the longer run and a concrete solution needs to be found.

- Critical charging infrastructure, such as sub-stations, becomes important in areas near mining operations to ensure a consistent and reliable power supply for the machinery.

- Given the essential role that these machines play in mining operations, uninterrupted access to power is very important to always maintain productivity and efficiency across all points within the mining site.

- Temperatures in mining sites can reach up to 60 degree Celsius, in such cases, different battery technologies can be explored based on their run time and thermal capacity for safety considerations.

- Collaboration and discussion between OEMs and Mine operators is necessary for OEMs to understand what products to develop.

- Although the industrial niche is ripe for revolution, the journey towards electrifying mining equipment is rife with complexities, demanding a symphony of collaboration among technology developers, mining giants, and regulatory bodies.

- The journey towards electrification in the industry relies heavily on collaboration, knowledge sharing, and investments. It’s not solely the responsibility of the government; early adopters and industry stakeholders must also be deeply committed and invested in advancing this sector.

- A combination of clean energy technologies would be required to fully address energy related challenges facing the mining industry.