Kenya’s domestic market is more than 56 million people and is considered one of East Africa’s core business and logistics hubs. Agriculture is the backbone of Kenya’s economy and central to the country’s development strategy. It accounts for 31.5% of Kenya’s GDP and employs 38% of the population.Despite this, food insecurity persists, with 4 million people facing extreme shortages during the 2022 drought. Limited access to markets and poor post-harvest practices contribute to 40% of food waste. The rising population, climate change, and disruptions in food supply chains pose further challenges, making an effective Cold Chain Infrastructure (CCI) crucial to mitigate many of these challenges.

A well-designed and developed cold chain can prevent food losses and reduce greenhouse gas (GHG) emissions related to food waste. Cold chains also ensure food security by reducing food price inflation, buffering the food supply, and overcoming seasonal shortfalls. This buffering mechanism dampens the price fluctuations that typically put vulnerable communities at risk of poverty and hunger and better supports the growth of farmers’ incomes.

Challenges faced by Kenya in growing CCI:

- Limited technical skills to provide after-sales services.

- Affordability – Cooling interventions need to be affordable and add value for farmers operating on thin margins. Usage-based payment models like CaaS, group ownership, and lease-to-own (PAYGO) can help reduce adoption barriers.

- Consumer awareness: There is limited awareness, especially among rural smallholder farmers, of the benefits of using cold chain solutions.

- Market dynamics and maturity: In Kenya, most food production is consumed within the country, and informal channels are common for selling products. For instance, over 99% of meat and 96% of fruits and vegetables are consumed locally through farmgate or domestic markets. Unlike export markets, domestic markets typically lack strict regulations and standards that require the use of a cold chain. While some players may use cold chain methods to extend produce shelf life, cooling is not mandatory.

- Lack of investment: Access to affordable debt and equity for service providers is needed, but the sector is still relatively young, and the financial needs are diverse. More established companies are ready for long-term patient capital and concessional loans. However, there is still a need for grants and programme support for market development activities

- Weak transportation infrastructure: Poor road conditions and traffic congestion increase travel time and increase the risk of perishable products becoming damaged and spoiled. In addition, poor roads and infrastructure can damage refrigerated trucks/vehicles, resulting in the leakage of high GWP refrigerants

- Inconsistent policies: Tariff regimes are inconsistent, and agro-based products have a favourable import duty, but it’s unclear if this is applicable to all value chains (e.g., meat and fish) and for components. The lack of national standards for energy performance and food quality also inhibits market growth

- Availability of equipment and suppliers: The development of a clean cold chain will have to be preceded by policies that encourage the import of cold-chain equipment in the country by local firms or even incentivise foreign firms to set up subsidiaries. That means that an entire industry will have to be developed or at least nurtured, including local manufacturers being encouraged/incentivised to undertake production.

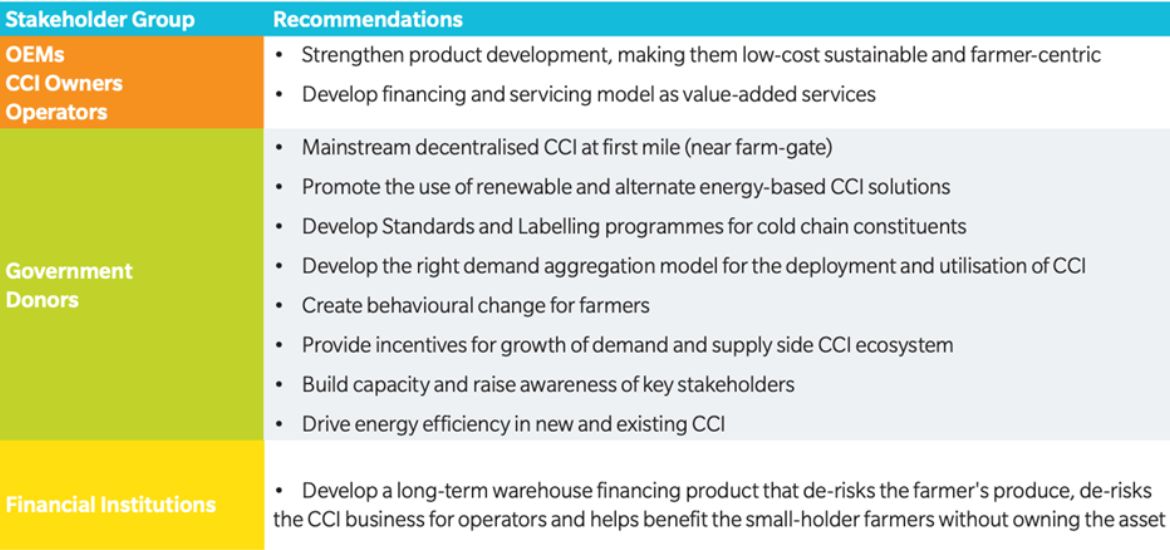

Key recommendations for carious stakeholder Groups in Kenya's CCI Sector

Challenges that Inhibit the Uptake of CCI Solutions

Several factors inhibit the adoption of CCI technologies on the side of both users and manufacturers. These challenges are as follows:

Financing challenges: Financing is challenging for enterprises/service providers and consumers/beneficiaries. Limited financing is available to enterprises creating and providing CCI, as well as to end consumers looking to acquire these technologies

Technological challenges: While technological innovation has been seen in the CCI sector, several challenges still exist. These include the availability of technicians required to manage installation and after-sales services, both critical to adopting new technologies. Meanwhile, poor-quality products negatively impact how customers view the entire sector, while limited local manufacturing capacity hinders local job creation and leads to import substitution.

Market and operational challenges: These include policy gaps regarding supply-side and demand-side incentives at the national and county levels. The immaturity of the market limits economies of scale regarding sector consolidation, bulk procurement, and the ability of individual companies to absorb commercial funding. As a result, most value chains remain primarily informal.

User challenges: The most common user-related challenge is limited familiarity with CCI solutions, including key product features like energy efficiency, usage and maintenance, and temperature control. Since most smallholder farmers are rain-dependent, the seasonality of their produce also impacts the utilisation rates of CCI assets, especially those using CaaS models. This has long-term impacts on technology providers’ margins, leading to more extended payback periods.

Potential Interventions to Increase the Uptake of CCI Solutions

Various strategies could be adopted to increase the uptake of CCI solutions in the country and to ensure they scale by 2030. Some of these strategies are as follows:

Increase patient capital in the sector: To promote CCI adoption, the sector requires more patient and catalytic capital, including long-term equity from commercial investors and grant financing. Targeted recipients are companies involved in CCI solutions and MFIs providing consumer financing for farmers.

- A first loss default guarantee programme in which a donor agrees to deploy grant capital as part of the investment to reduce losses in case the ROI is negative, thus catalysing participation from more commercial co-investors.

- Results-based or performance-based financing, where an investor or financier provides patient capital to achieve measurable impact; this could be the amount of food the CCI solution “saves” from wastage.

- Public Private Partnerships (PPPs) include a mechanism whereby the government provides financing for an asset while the private sector player is responsible for its repair, maintenance, and the technical support required to ensure sustainability.

Re-evaluate the tax regime and reduce prices: The tax regime for CCI parts and components significantly raises their prices, accounting for almost 40% of production costs. This high cost hinders CCI adoption, particularly at the initial stage. Re-evaluating the tax system is crucial, and efforts should be made to provide tax subsidies through multistakeholder taskforces. This will lead to more affordable CCI solutions, incentivizing their uptake in the market.

Increase donor programmes that promote market development activities: Increase donor-sponsored programs to promote market development of CCI assets. Focus on building technical skills, local manufacturing, and after-sales services. Educate farmers and consumers to boost adoption. Fund successful pilots to reduce risk perception among stakeholders.

Increase processing and exports: To promote CCI technologies, Kenya should focus on increasing local food processing and exports, while adhering to Global Agricultural Practices, including cold chain requirements, to meet quality standards for export markets.

To promote CCI technologies, Kenya needs dedicated policy support and full implementation. Specific regulations can cover optimum produce temperature, pricing, and certified technical providers. Publicly funded capacity building for cooling engineers can enhance skills. Tailored recommendations for different markets can further boost CCI adoption.

For the household refrigerator market:

- Resolve PAYG compatibility, appropriate system controls and improved reliability.

- Develop financing solutions through micro-finance and PAYG contracts in mini-grid markets.

- Provide after-sales technical support and the means to deliver appliances to remote regions.

For the small commercial refrigerator market:

- Encourage development of appliances for target markets and collaborate with regional business associations and SACCOs.

- Design “solar stalls,” soft drink coolers, and portable coolers for farmers and producers, emphasizing reliability.

- Develop financial case templates and suitable financing packages for entrepreneurs.

- Ensure after-sales technical support for sustained operations.

For the commercial ice-maker market:

- Encourage targeted appliance development and collaboration with farmers’ cooperatives.

- Focus on small agricultural, meat, fish, and dairy storage and transportation systems.

- Provide financial case templates and suitable financing options.

- Establish after-sales technical support.

Although use cases vary across value chains, overall, CCI in Kenya is underdeveloped in the agricultural sector, resulting in significant quantities of food lost yearly due to a lack of cold chain technology. CCI manufacturers and distributors must ensure that their products correspond to the needs and capacities of the first-mile market segment, particularly concerning the power sources they use and the payment models they adopt. In supporting innovations in cold chain technology, there should be a particular focus on products powered by renewable energy.

However, solving this problem requires more than the proper technology; a system-wide approach combining education, financing, and policy changes is needed to fully realise the cold chain market’s potential and for Kenyans to reap its benefits eventually.

Access the full report here